Isitezi se-PVC sivame kakhulu ekuhlobiseni kwehhovisi lesimanje, ngezinzuzo zokungangeni kwamanzi, ukuvikela umlilo, ukuthulisa, njll .Izinyathelo zokubeka i-PVC floor ngesikhathi sokuhlobisa zimi kanje:

1. Thela i-self leveling slurry exubile endaweni yokwakha, izogeleza futhi ihlele phansi ngokwayo.Uma ubukhulu bomklamo bungaphansi noma bulingana no-4mm, idinga ukusebenzisa isikrufu samazinyo esikhethekile ukunwaya kancane.

2. Ngemva kwalokho, izisebenzi zokwakha zizogqoka izicathulo ezikhethekile ezinama-spiked futhi zingene endaweni yokwakha.Isilinda somoya esikhethekile esizilinganisa sizosetshenziselwa ukuzigingqa ngobumnene endaweni ezilinganisa yona ukuze kudedelwe umoya oxutshwe ekuxutshweni, ukuze kugwenywe indawo ephawulwe ngebhamuza kanye nomehluko wobude bokusetshenziswa kubonwa.

3. Sicela uvale isiza ngokushesha ngemva kokuqedwa kokwakhiwa, wenqabele ukuhamba phakathi kwamahora angu-5, gwema ukungqubuzana kwezinto ezinzima phakathi namahora ayi-10, bese ubeka phansi i-PVC ngemva kwamahora angu-24.

4. Ekwakhiweni kwasebusika, phansi kufanele kubekwe amahora angama-48-72 ngemuva kokwakhiwa kokuzilinganisa.

5. Uma kudingekile ukuqeda ukupholisha i-self leveling, kufanele kwenziwe ngemuva kokuba usimende wokuzilinganisa wome ngokuphelele.

Ukuhlolwa kwezimo zokwakha

1. Sebenzisa imitha lokushisa kanye nokuswakama ukuze uthole izinga lokushisa kanye nomswakama.Izinga lokushisa lasendlini kanye nezinga lokushisa elingaphezulu kufanele libe ngu-15 ℃, esikhundleni sokwakha libe ngaphansi kuka-5 ℃ nangaphezulu kuka-30 ℃.Umswakama womoya ohambisanayo ofanele ukwakhiwa uzoba phakathi kuka-20% no-75%.

2. Umswakama we-base course uzohlolwa yisihloli sokuqukethwe komswakama, kanti umswakama wesifundo esiyisisekelo uzoba ngaphansi kuka-3%.

3. Amandla esifundo esiyisisekelo akumele abe ngaphansi kwemfuneko yamandla kakhonkolo C-20, ngaphandle kwalokho ukuzilinganisa okufanele kuzokwamukelwa ukuze kuqiniswe amandla.

4. Umphumela wokuhlolwa ngesihloli sokuqina kuyoba ukuthi ubulukhuni bobuso benkambo eyisisekelo akumele bube ngaphansi kuka-1.2 MPa.

5. Ukuze kwakhiwe izinto zaphansi, ukungalingani kwesifundo sesisekelo kuzoba ngaphansi kuka-2mm ngaphakathi komkhawulo oqondile wama-2m, ngaphandle kwalokho, ukuzilinganisa okufanele kuzokwamukelwa ukuze kulinganiswe.

Ukuhlanza ubuso

1. Sebenzisa umshini wokugaya waphansi onama-watts angaphezu kuka-1000 nezingcezu zokugaya ezifanele ukuze upholishe iphansi lilonke, khipha upende, iglu nezinye izinsalela, umhlabathi onamaqhuqhuva nomhlabathi oxekethile, nomhlabathi ongenalutho nawo kufanele ususwe.

2. Isitezi sizococwa futhi sihlanzwe ngesicoci se-industrial vacuum esingekho ngaphansi kwama-Watts angu-2000.

3. Ukuze uthole imifantu phansi, iziqinisa zensimbi engagqwali kanye ne-polyurethane enamathelayo engangeni manzi ingasetshenziswa ukugandaya isihlabathi se-quartz ngaphezulu ukuze silungiswe.

Ukwakhiwa kwe-ejenti yesixhumi esibonakalayo

1. Isizinda esimuncayo, esifana nokhonkolo, udaka lukasimende kanye nesendlalelo sokulevelitha, sizovalwa futhi sifakwe i-ejenti yokwelapha yezinjongo eziningi namanzi ngesilinganiso esingu-1:1.

2. Esifundweni sesisekelo esingamunceli, esifana nethayela le-ceramic, i-terrazzo, imabula, njll., kunconywa ukusebenzisa i-ejenti yokwelashwa kwe-interface eminyene ukuze kufakwe phansi.

3. Uma umswakama we-base course uphezulu kakhulu (> 3%) futhi ukwakhiwa kudinga ukwenziwa ngokushesha, i-epoxy interface yokwelapha i-ejenti ingasetshenziselwa ukwelashwa kokuqala, inqobo nje uma umswakama wesifundo sesisekelo hhayi ngaphezu kuka-8%.

4. I-ejenti yokwelapha esibonakalayo isetshenziswe ngokulinganayo ngaphandle kokunqwabelana okusobala koketshezi.Ngemuva kokuthi ubuso be-ejenti yokwelapha isikhombimsebenzisi somile emoyeni, ukwakhiwa okulandelayo kokuzilinganisa kungenziwa.

Isilinganiso sokuzilinganisa

1. Thela iphakethe lokuzilinganisa ebhakedeni lokuxuba eligcwele amanzi ahlanzekile ngokwesilinganiso esibekiwe sikasimende wamanzi, bese uthela futhi uhlanganise ngesikhathi esifanayo.

2. Ukuze uqinisekise ngisho nokuxubana kokuzilinganisa, kuyadingeka ukusebenzisa umshini wokugaya ugesi onamandla, ophansi ngesivinini esine-mixer ekhethekile yokuxuba.

I-3.S ifake ku-slurry efanayo ngaphandle kwe-caking, vumela ukuthi ime futhi ivuthwe cishe imizuzu engu-3, bese ugoqa futhi kafushane.

4. Inani lamanzi elengeziwe lizohambisana ngokuqinile nesilinganiso sikasimende wamanzi (sicela ubhekisele emiyalweni ehambisanayo yokuzilinganisa).Amanzi amancane kakhulu azothinta uketshezi, okuningi kuzonciphisa amandla ngemuva kokwelapha.

Ukwakhiwa kokuzilinganisa

1. Thela i-self leveling slurry exubile endaweni yokwakha, izogeleza futhi ihlele phansi ngokwayo.Uma ubukhulu bomklamo bungaphansi noma bulingana no-4mm, idinga ukusebenzisa isikrufu samazinyo esikhethekile ukunwaya kancane.

2. Bese, izisebenzi zokwakha zizogqoka izicathulo ezikhethekile ezinezipikili, zingene endaweni yokwakha, zisebenzise isilinda esikhethekile esizilinganisa emoyeni ukuze zigiqeke ngobumnene endaweni ezilinganisa yona, zidedele umoya oxutshwe ekuxutshweni, futhi zigweme indawo enebhamuza kanye nesixhumi esibonakalayo. umehluko wobude.

3. Sicela uvale isiza ngokushesha ngemva kokuqedwa kokwakhiwa, ungahambi phakathi kwamahora angu-5, gwema ukushayisana kwento esindayo kungakapheli amahora ayi-10, bese ubeka phansi ngemva kwamahora angu-24.

4. Ekwakhiweni kwasebusika, iphansi kufanele libekwe amahora angu-48 ngemva kokuzakhela ngokwakho.

5. Uma kudingekile ukuqeda ukupholisha ukuzilinganisa, kufanele kwenziwe amahora angu-12 ngemva kokwakhiwa kokuzilinganisa.

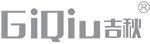

Ukugandaya ngaphambili

1. Kokubili ikhoyili kanye nezinto zokuvimba kuzobekwa endaweni isikhathi esingaphezu kwamahora angama-24 ukubuyisela inkumbulo yezinto kanye nokugcina izinga lokushisa lihambisana nendawo yokwakha.

2. Sebenzisa ithuluzi lokunquma elikhethekile ukusika nokuhlanza unqenqema lwekhoyili.

3. Lapho ubeka amabhlogo, akufanele kube khona ukujoyina phakathi kwamabhulokhi amabili.

4. Uma ubeka izinto ezigoqiwe, ukugqagqana kwezingcezu ezimbili zezinto zokwakha kuzosikwa ngokugqagqana, okuvame ukudingeka ukuthi kweqe ngo-3cm.Naka ukugcina ummese owodwa usikiwe.

Gluing

1. Khetha i-glue efanele kanye ne-rubber scraper phansi ngokusho kobudlelwane obuhambisanayo bamatafula asekelayo kulo mhlahlandlela.

2. Uma impahla egoqiwe igandaywe, isiphetho sento eboshiwe siyogoqwa.Hlanza kuqala iphansi kanye nengemuva lomqulu, bese ukhuhla ingcina phansi.

3. Uma uvula ibhulokhi, sicela uphendule ibhulokhi ukusuka phakathi kuya ezinhlangothini zombili, futhi uhlanze indawo ephansi nephansi bese unamathisela ngeglue.

4. Ama-adhesive ahlukene azoba nezidingo ezahlukene ekwakhiweni.Sicela ubheke imiyalelo yomkhiqizo ehambisanayo yokwakha.

Ukubeka nokufakwa

1. Ngemva kokuba iphansi linamathiselwe, qala ngokusunduza bese ucindezela indawo ephansi ngebhulokhi yokhuni ethambile ukuze ilingane futhi ukhiphe umoya.

2. Bese usebenzisa i-roller yensimbi engu-50 noma 75 kg ukuze ugoqe phansi ngokulinganayo futhi uphungule unqenqema olusontekile lwelunga ngesikhathi.

3. Iglue eyeqile endaweni ephansi kufanele isulwe ngesikhathi.

4. Ngemuva kwamahora angama-24, faka i-notch bese ushisela futhi.

Slotting

1. I-Slotting kumele yenziwe ngemuva kokuthi i-glue iqiniswe ngokuphelele.Sebenzisa i-slotter ekhethekile ukufaka eduze kwejoyinti.Ukuze wenze i-welding iqine, i-slotting ngeke ingene phansi.Kunconywa ukuthi ukujula kwe-slotting kube ngu-2/3 wogqinsi lwephansi.

2. Ekugcineni lapho i-seamer ingakwazi ukusika, sicela usebenzise i-seamer eyenziwa ngesandla ukuze usike ngokujula nobubanzi obufanayo.

3. Ngaphambi kokushisela, uthuli nemfucumfucu esele emseleni kuyosuswa.

Ukushisela

1. Isibhamu sokushisela ngesandla noma imishini yokushisela okuzenzakalelayo ingasetshenziselwa ukushisela.

2. Izinga lokushisa lesibhamu sokushisela kufanele libekwe cishe ku-350 ℃.

3. Cindezela i-electrode ku-groove evuliwe ngesivinini esifanele sokushisela (ukuqinisekisa ukuncibilika kwe-electrode).

4. Uma i-electrode isipholile uhhafu, sebenzisa i-electrode leveler noma i-cutter yanyanga zonke ukuze usike cishe indawo lapho i-electrode iphakeme kunendiza yaphansi.

5. Uma i-electrode isipholile ngokuphelele, sebenzisa i-electrode leveler noma i-cutter yanyanga zonke ukuze usike ingxenye esele ye-convex ye-electrode.

Isikhathi sokuthumela: Jan-20-2021